NEWS

Professional design, development and production of digital encoder, electronic switch and high and low voltage connector

Information classification >

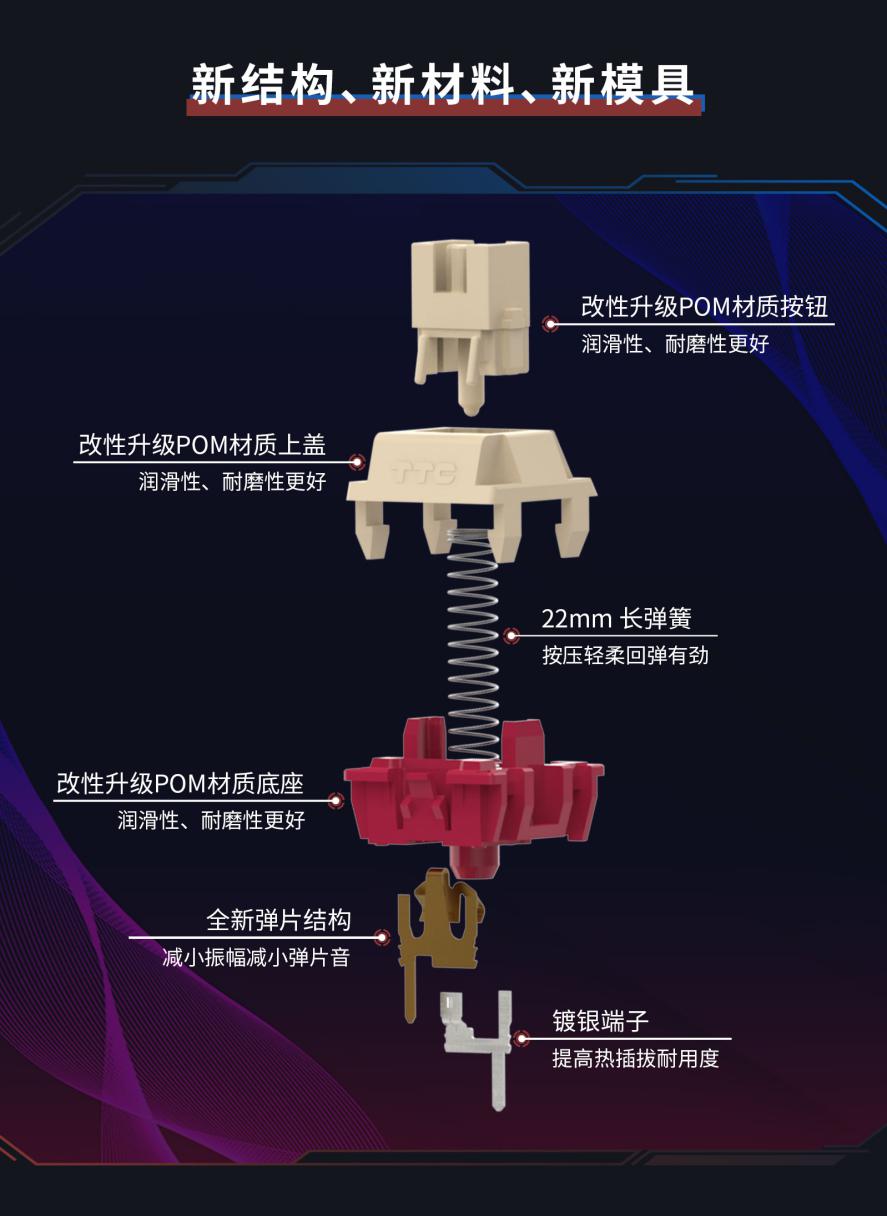

Reduce amplitude, reduce the sound of leaf spring-- TTC releases Iron Keyswitch

2023-04-20 10:28

On April 20th, 2023, TTC Electronics Co., Ltd. officially launched a new structural keyswitch -- TTC Iron Keyswitch. This keyswitch adopts new structure and new materials, aiming to create super core keyswitch products for players.

What is the the sound of leaf spring?

As we all know, the ON-OFF of mechanical keyswitch is to control the closure or partition of fixed terminals by pushing or releasing elastic metal pieces by the touch feet of the keyswitch core to realize the on-off of electronic signals. In the process of pressing the core of keyswitch, especially in the game or high-speed tapping the keyswitch, the elastic metal pieces is rapidly tapped and bounced back at high frequency, which will inevitably produce leaf spring vibration and noise, which is what users call "the sound of leaf spring" and "the sound of striking iron".

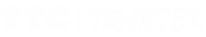

Theoretical analysis of force of elastomer

As can be seen from the figure above, the radian (oscillation amplitude) of the elastomer bouncing back from point A1 to point A2 is significantly greater than that from point B1 to point B2. Therefore, the farther the position on the elastomer is from the fixed origin 0, the greater the spring back motion of the elastomer. On the contrary, the closer the distance from the fixed origin 0, the smaller the elastomer rebound motion amplitude.

New structure -- reduce amplitude, reduce the sound of leaf spring

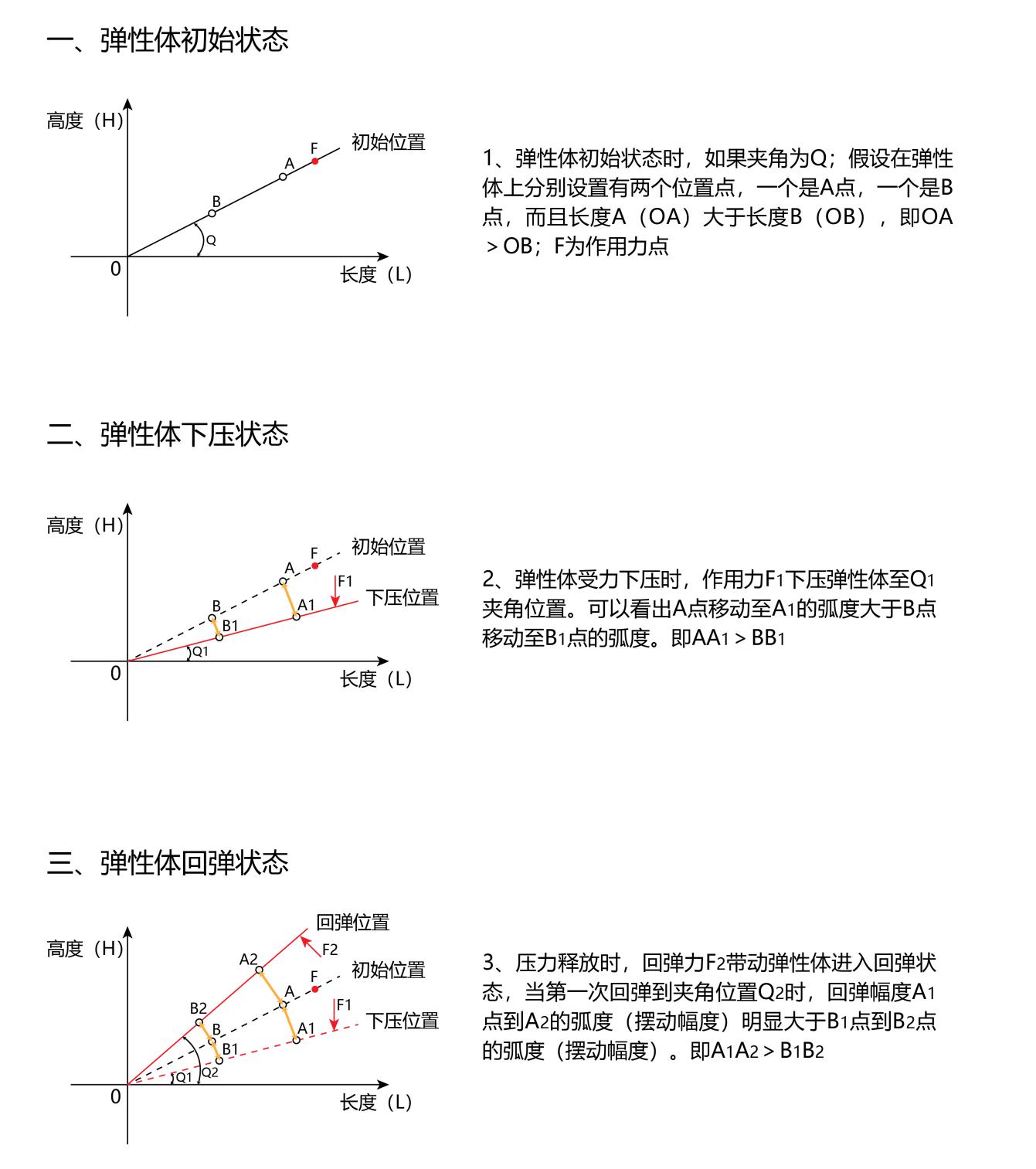

Amplitude and loudness

According to the above physical knowledge, the loudness of a sound is closely related to its amplitude. The larger the amplitude of the sounding body, the larger the loudness of the sound. Can the sound of leaf spring of keyswitch be reduced?

In order to reduce the noise caused by leaf spring vibration, TTC adopts the scheme of decreasing the amplitude of leaf spring to reduce the sound of leaf spring in the design of the leaf spring structure with originality. That is to shorten the length of the longitudinal moment arm of the leaf spring A size and B size, that is, the A size is reduced from the original 6.6mm to 5.4mm, and the B size is reduced from the original 5.2mm to 4.2mm. At the same time, the size C of the transverse pin spacing of the leaf spring is reduced from 7.3mm to 5.7mm. Thus, the amplitude of the leaf spring of the keyswitch is greatly reduced and the sound of leaf spring produced by the leaf spring vibration is effectively reduced.

New material - The first keyswitch thatTTC uses modified and upgraded POM material

What is Saigang?

Saigang is just like steel.

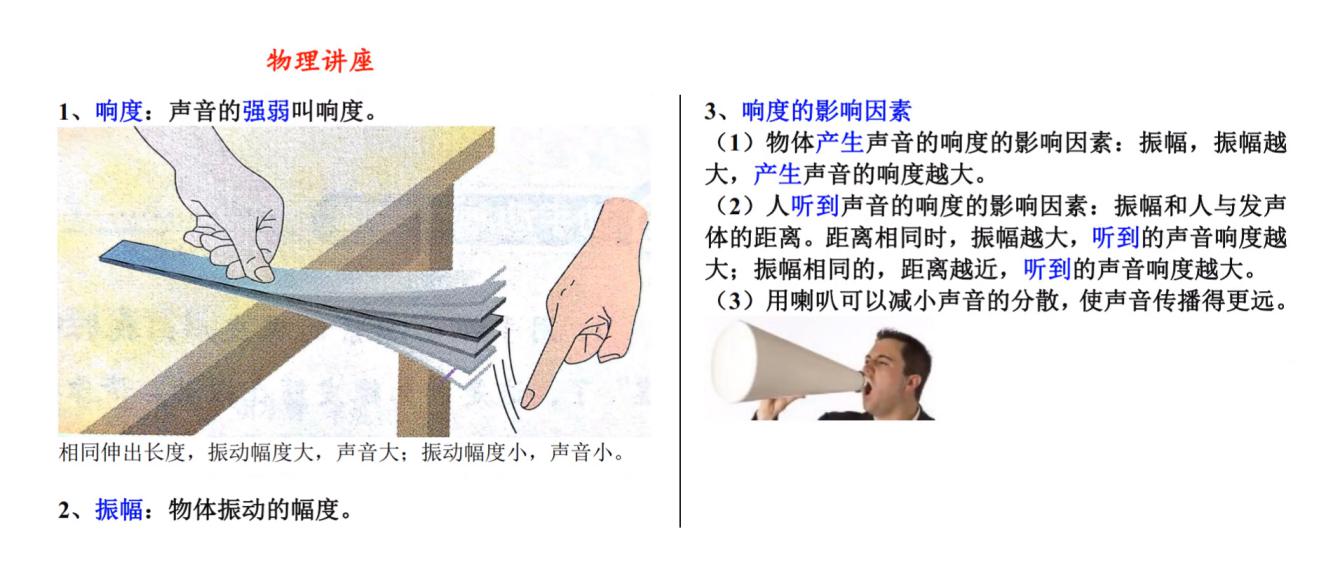

Saigang is POM. POM (polyformaldehyde) is a thermoplastic crystalline polymer, Chinese: polyformaldehyde, also known as acetal resin, polymethylene oxide. POM plastic is a linear polymer with no side chain, high density and high crystallinity, which is one of the five major engineering plastics.

POM(Saigang) is a kind of engineering plastic with excellent comprehensive performance. It has hardness, strength and rigidity similar to steel.

However, POM also has some defects in performance, such as molding shrinkage rate is large, reaching 1.5%-3%, while the PC material commonly used in keyswitch is generally 0.5%-0.7%, nylon is 0.3%-0.6%, and the trouble is that the shrinkage rate of POM changes greatly, generally in 1.5% to 3%, Directly caused by the injection molding of the product size deviation is large, consistency is not good, accuracy is also affected, at the same time, processing is easy to heat decomposition, toughness is low. That is to say, if a plastic part with a length of 10mm, in the case of the same mold size, the size deviation of POM material injection molding will be 0.15mm [10x (3%-1.5%)], and the size deviation of PC material is only 0.02mm [10x (0.7%-0.5%)], The difference of size accuracy between the two is 7.5 times.

In addition, POM is a crystalline thermoplastic, but the melting point is low, melting point between 165℃ and 175℃, can not pass the wave peak solder furnace process. Reflected in the keyswitch, the foot of keyswitch can not be welded, otherwise the POM base will melt and deform. Of course, the keyswitch is not welded but hot-plug mode is no problem.

In order to improve the comprehensive performance of POM material, the method of modification and upgrading is generally used in material science. POM material modification and upgrading mainly through physical and mechanical methods in POM to add inorganic or organic substances, or will be different types of polymer and its blending, or chemical methods to achieve poly-formaldehyde copolymerization grafting, cross-linking, or the above various methods combined, and used to improve its dimensional stability, reduce friction, wear coefficient. At the same time, the rigidity, strength, notch sensitivity and impact resistance can also be greatly improved. Therefore, the modified and upgraded POM Saigang material has excellent performance in high wear resistance and high self-lubricity as well as dimensional accuracy and stability.

At present, the specific methods to improve POM are:

1. Add plastic Wang Teflon (PTFE), high density polyethylene (HDPE), ultra-high molecular weight polyethylene (UHMWPE), high molecular weight silicone and other polymer materials with low friction coefficient;

2. Add silicone oil, mineral oil, grease and other lubricants and grease;

3. Add MoS₂, graphite and other inorganic powder lubricating materials;

4. Use grafting, block and other means to introduce lubricating chain segments on the POM molecular chain;

5. Add glass fiber, carbon fiber, aramid and other fibrous materials;

6. Add copper powder, lead powder, zinc powder and other metal powder;

With the development of science and technology, the market demand is constantly changing, how to innovate a better new POM composite material, the innovation and breakthrough of material science is always on the road.

TTC iron keyswitch, keyswitch core, top cover, base all adopt international brand new modified and upgraded POM(Saigang) material, excellent performance in keyswitch surface lubrication, ultra-low friction coefficient and high wear loss, the more used the more smooth. There are two kinds of keyswitch released this time. One is iron keyswitch, which is a linear keyswitch. The other is the iron brown keyswitch, which belongs to the advance large tactile keyswitch.

Due to the wide range of POM plastic molding shrinkage rate change, generally between 1.5% to 3%, and the size of the plastic parts after injection molding is greatly affected by the pressure of the injection molding machine is stable, the injection cycle time is accurate and the change of various parameters. Therefore, in order to ensure the accuracy and consistency of the parts after injection molding, an injection molding machine with high precision and stability is indispensable.

In view of the characteristics of POM material, TTC refuses to choose the traditional hydraulic injection molding machine, but adopts the latest ADS electric system automatic high-precision injection machine from JSW company, an international brand. With the industry's fastest calculation 62μs ultra-high speed servo motor control system, using IWCS to control the sol density of the front section, effectively inhibit the dynamic deviation of the total amount of plastic and parts output, to achieve high precision and high stability of keyswitch size quality. Because the oil pressure system is used, the products after injection molding are of course resistant to oil pollution and instability.

TTC precision parts workshop real scene shooting

New structures, new materials, new experiences

TTC iron keyswitch is a linear fast keyswitch with 1.4mm quick trigger, 41gf comfortable operating force, 3.8mm total operating force. TTC iron brown keyswitch, is an advance large tactile keyswitch, 55gf tactile force, 42gf operating force, 3.3mm total operating force. The keyswitch is made of modified and upgraded POM material. The design of extended keyswitch core touches the bottom, and the audio consistency of tapping and bouncing is excellent. Keyswitch factory with precision lubrication, ready to use, combined with POM material self-lubricating, the more you use it, the smoother it gets..

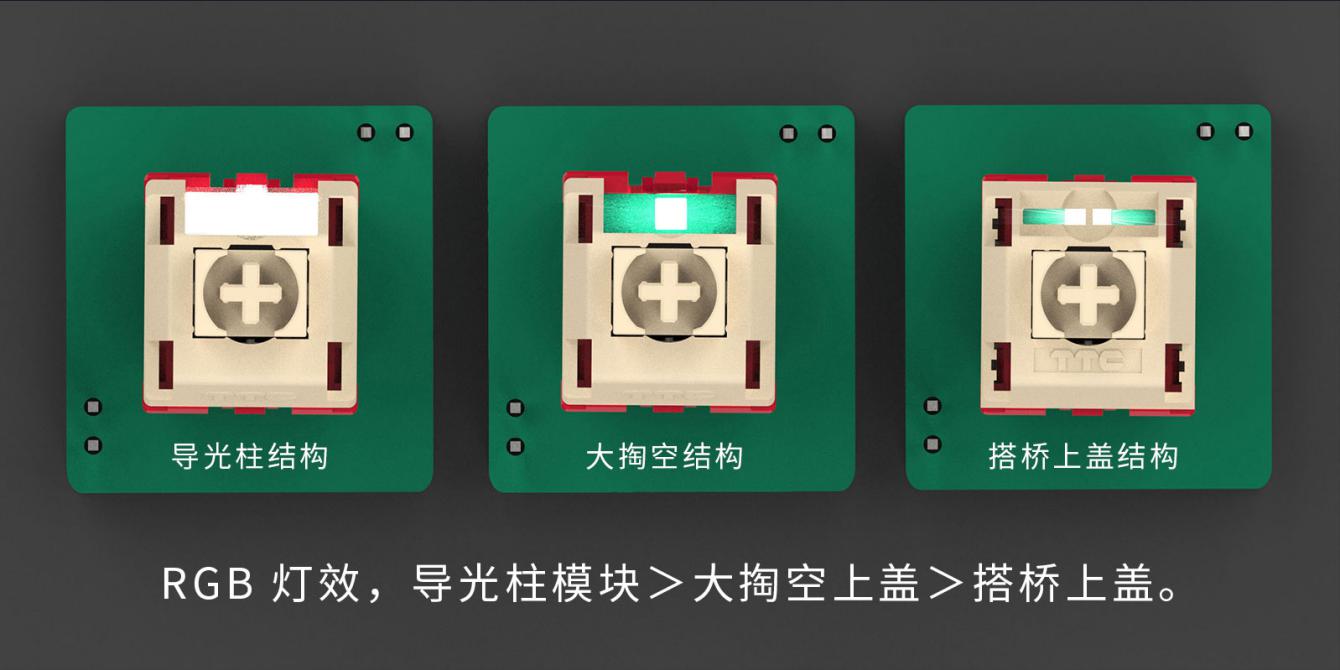

Independent light guide module structure Enhanced light effect RGB Uniform without noise.

Since POM raw material is opaque, in order to solve the problem of light transmission, the iron keyswitch is designed with a large hollow-out base and a large hollow-out top cover to expand the LED light transmission window. In order to increase the RGB light guide effect, users can also choose to carry TTC independent light guide module, RGB light effect is brighter, more balanced, no noise.

(The above information comes from the Internet)

Warm note: The structure has applied for national patent. Respect and protect intellectual property rights!

Related news